For calculating strain hardening exponent n from the stress strain curve of heat treated samples I used non-linear curve fitting in inelastic region of the curve and used the equation stressK. Could someone please explain why an increase in strain hardening exponent n results in less material necking from this equation.

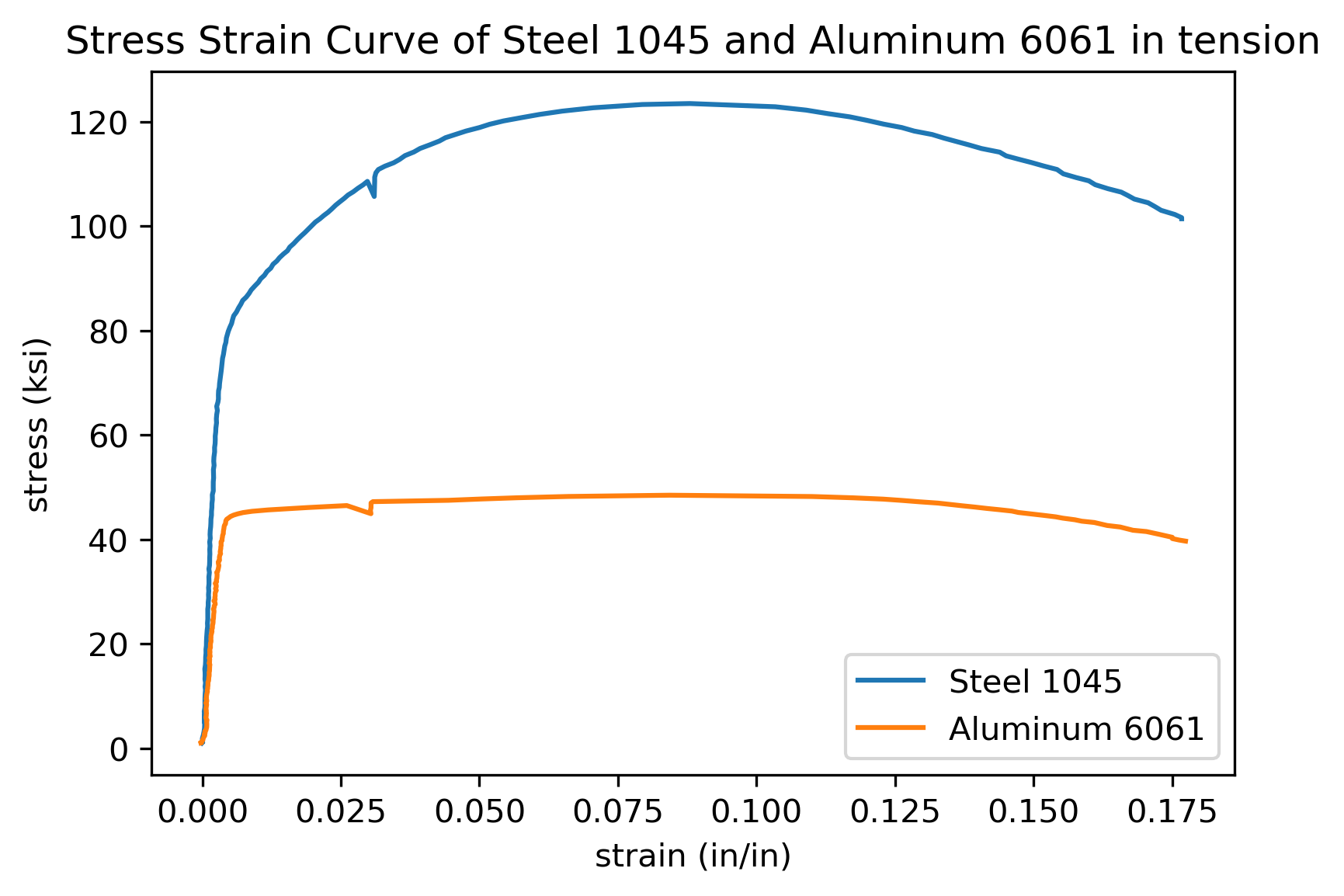

Plotting A Stress Strain Curve With Python And Matplotlib Python For Undergraduate Engineers

Stress=k*strain^n. Hello According to the power law StressKstrainn. Normal stressKstrainn High value of n will have a significant increase in strength with a small amount of deformation. K displaystyle K is the strength coefficient.

O Stress Kstrainn Changes to stress-strain curve o Increase temp Ductility up Toughness up Yield stress down Modulus of elasticity down. Here e refers to the base of natural logarithm which.

The relationship between the tensile strength TS the strength constant K and the strain hardening index n is given by TS K nen. Plastic or Bingham behavior is represented by stress --kl 4-r strain. Plastic or Bingham behavior is represented by stress k 1 η strain where η is called the plastic viscosity.

Hello is it possible to define plastic region of a material in abaqus by giving kn values from stresskstrainn like in stamping FEA softwares. Where n is the strain-hardening exponent and K is the strength coefficient.

Where K and n indicate the relationship between true stress and true strain for the spring material stress Kstrain n. In terms of equations 25 m is determined as 003. Use your own judgement4.

And whats best material model for wire insulation sleeve on the copper conductor in electric wires. Use FK f Y f A K f 104Dh Ans. Small n value will show little change in strength with plastic deformation.

Initialization 202不锈钢v30501 E 203 109. ElasticStress E elasticStrain. A value of 0 means that a material is a perfectly plastic solid while a value of 1.

7 101112 focus more cause have more points in grading 3. Pseudoplastic or power-law behavior is represented by stress k strain n n 1 where k is called the consistency index. Yf KStrainn Avg.

Characteristics such as friability abrasiveness flammability etc. Several classes of non-Newtonian behavior are recog- nized for suspensions. 10 is satisfied by the data Fig.

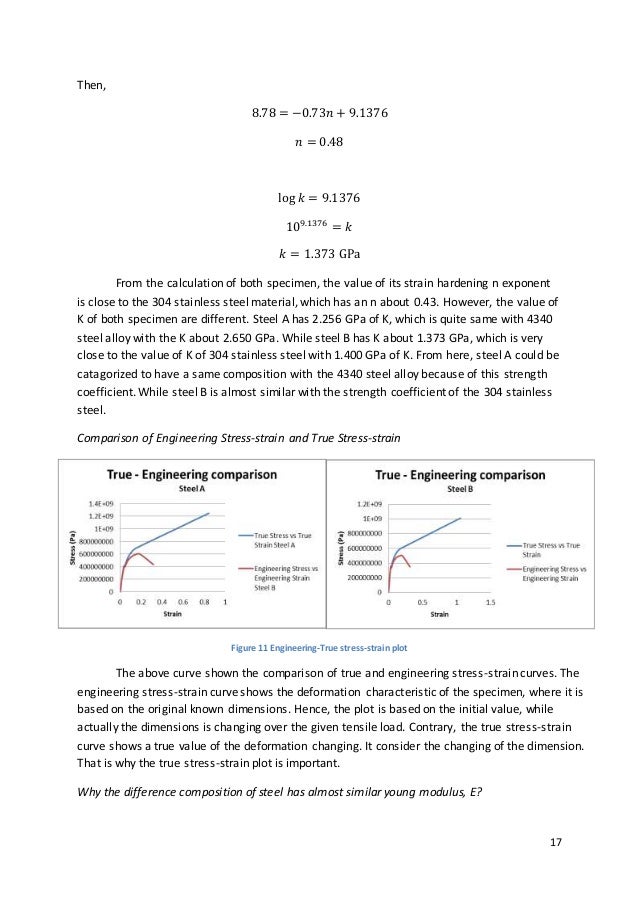

This may just require equation from the analysis section and not discussion. Stress kstrain n 1 The capacity of pneumatic-conveying systems depends on several where k is called the consistency index. Elastic Stress 80000 Plastic Stress True Stress 3 174 HTS The next issue of 60000 Linear Plastic Stress Kstrainn Technical Tidbits 2 40000 Engineering Stress log stressnlogstrainlogK continues the 1 20000 y 00713x 51577 discussion on strain 0 0 hardening.

This what i want in the discussion part 34689 should not be more than 3 or 4 sentences. True stress-strain curves with resulting K and n values that. Stress K Strain N y Effective material density Pt Ro P t Dimensionless Ho Ro Initial vessel radius R1 Maximum vessel radius P Pressure retaining ability of wall H Wall thickness 0 In addition to the inertial effect the wall motion is retarded by the tangential wall stresses which increase through.

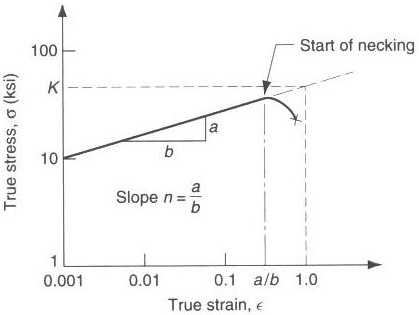

A log-log plot of true stress and true strain up to maximum load will result in a straight-line if Eq. 0305已核304在04以上 K 386 109. After completing this test you are informed that the tensile specimen had been cold-worked some amount before it was machined and tested and that in the annealed state StressKstrainn with.

Extra bits you dont need Verify that the modulus is near 210 GPa. The value of the strain hardening exponent lies between 0 and 1. Flow stress KStrainn n1 2000035000Strain0414 Strain0572lnAoAf AoAf177 Af0565Ao Reduction area0435Ao 10.

The linear slope of this line is n and K is the true stress at e 10 corresponds to q 063. UltimatedStress 520 106. Pseudoplastic or power-law behavior is rep- resented by stress k strain n 1 where k is called the consistency index.

According to the spring material used K and n are chosen as 410 MPa and 01 respectively. Solve for final strain and obtain the final dimensions using constant volume condition.

Cee 3710 Strength Versus Stiffness

Https Engineering Purdue Edu Xe Forms 20for 20website Fe 20review Slides Problemsandsolution1 Material 20science Problems Pdf

Http Audi Nchu Edu Tw Wenjea Mechanical103 Chapter 5 Pdf

Kurva Tegangan Regangan Stress Strain Curve Pada Uji Tarik Ets Worlds

Importance Of Yield Strength Plastic Deformation To Civil Engineers

Hardening Coefficient An Overview Sciencedirect Topics

What Is The Difference Betweem True Stress And Flow Stress

Https Engineering Purdue Edu Xe Forms 20for 20website Fe 20review Slides Problemsandsolution1 Material 20science Problems Pdf

Formula For The True Strain And Stress In The Gleeblee3800 Modules Download Table

Stress Strain Curve For Mild Steel With Stress Strain Relationship Mechanical Engineering

Hooke S Law Stress And Strain Revisited Physics

Tensile Yield Strength An Overview Sciencedirect Topics

Http Audi Nchu Edu Tw Wenjea Mechanical103 Chapter 5 Pdf

Strain Hardening Definition Ductility Effects Of Strain Hardening

Stress And Strain Simple Explanation Engineering Discoveries Stress Strains Explanation

Lab Report Engineering Materials Lab Tensile Test

Formulas Used To Calculate The Compressive And Tensile Mechanical Download Scientific Diagram

Stress Strain Curve An Overview Sciencedirect Topics

0 comments