It is reported that the stress ratio have. Plotted on a Haigh diagram with lines of constant life drawn.

Effect Of R Ratio On Crack Growth Left Crack Growth Variation With Download Scientific Diagram

This includes the design stress from.

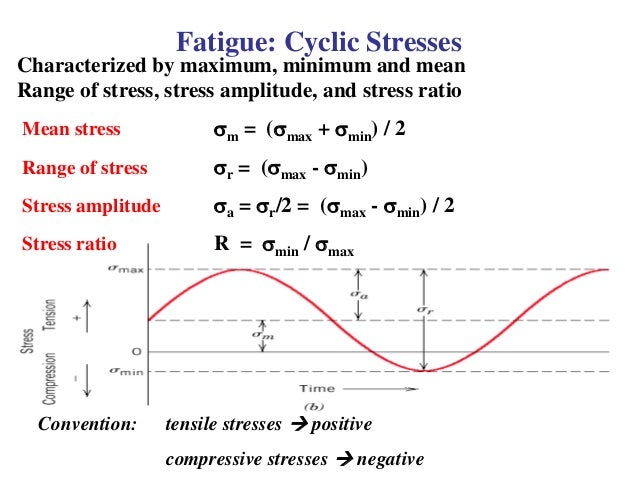

R stress ratio. Moreover the damage mechanisms under tension are different from those under compression. Stress ratio A or R Stress ratio A or R The algebraic ratio of two specified stress values in a stress cycle. One important point to note is that the all sources of stress will factor into the fatigue performance of a component.

In general the crack propagation rate of a given crack subjected to a constant amplitude loading depends primarily on the range of stresses in the fatigue cycle σ max σ min and on the crack length. This would result in an R ratio between -1 and 0. Stress ratios are the ratios between under and over stress with regard to a particular type of load such as torque.

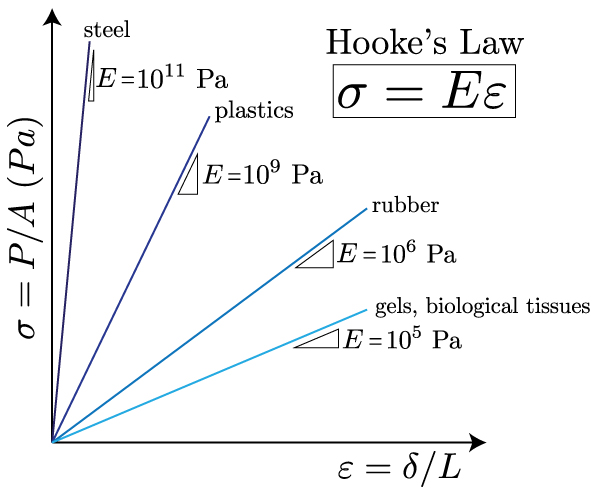

If the stresses are partially re versed Rbecomes a negative number less than 1. The stress ratio R is usually defined as minimum stress value divided by maximum stress value which leads to values between - and 1. Stress ratio R smin smax Eq 144 Amplitude ratio A sa sm 17R 1R Eq 145 142 High-Cycle Fatigue High-cyclefatigueinvolvesalargenumberof cycles N4105 cycles and an elastically applied stress.

The endurancefatigue strength of the material is found out using rotating bending fatigue testing equipment at stress ratio R-1 which is fully reversed condition loading cycle. Applying a stress ratio R varying from - 07 to 07. This could be the case in some switch and relay contacts.

A stress ratio R of 1 indicates no variation in stress. As a result a typical CLD for composite materials is shifted to the right-hand side and the highest point is located away from the line corresponding to zero mean stress σ m 0 or else the line representing the reversed SN curve with a ratio between the minimum and maximum applied stress R 1. Stress ratio fatigue is the ratio of minimum and maximum stress amplitudes and is represented as R σminσmax or stress_ratio Minimum compressive stressMaximum tensile stress.

Sm smax smin 2 Eq 143 Two ratios frequently used in presenting fatigue data are. If the stresses are fully reversed the stress ratio R becomes -I. If the stress is cycled between two tensile stresses the stress ratio R becomes a positive number less than 1.

Two commonly used stress ratios are 1 the ratio of the alternating stress amplitude to the mean stress A SaSm and 2 the ratio of the minimum stress to the maximum stress R SminSmaxs. 522 The stress ratio and amplitude ratio valuescorresponding to several common loadings - Fully reversed R-1 A - Zero to max R0 A1 - Zero to min R A-1. The stress ratio R is the ratio of minimum stress σ min to the maximum stress σ max.

Rmse 008498762 max resid 01882996 Run 19 stress 9248478e-05. Minimum compressive stress in a cyclic load during fatigue and Maximum tensile stress in a cyclic load in fatigue. The mean stress is the algebraic average of the maximum and minimum stress in the cycle.

Stress ratio effects on fatigue crack growth. For fully-reversed loading conditions R is equal to -1. The effect of the stress ratio R on the crack-growth rate can be accounted for by crack closure.

523 Haigh Diagram - The results of a fatigue test using a nonzero mean stress are. However Elbers empirical formula for this effect cannot be valid for negative R ratios. R is defined as the ratio between the min and max stress and depending its value has an impact on the fatigue test results by decreasing the stress amplitude as stress ratio decreases for the same number of life cycles.

If the stress is cycled between a maximum stress and no load the stress ratio R becomes zero. The results were analysed using the linear elastic fracture mechanics approach. Also an empirical effective stress.

Two ratios that are often defined for the representation of mean stress are the stress ratio R and the amplitude ratio A. Rmse 004303402 max resid 007046762 Run 17 stress 01170156 Run 18 stress 9509689e-05. It is also influenced by the stress ratio R σ minσ max.

They showed that the increase in both positive and negative R caused increased fatigue crack growth rates. Rmse 01360596 max resid 02699309 Run 15 stress 03238549 Run 16 stress 9492202e-05. Here R -1 and defines a pure alternating stress ratio R 0 defines a pure pulsating stress ratioR -1 and defines a pure alternating stress ratio R 0 defines a pure pulsating stress ratio.

R05 Fluctuating Stress Mininum Stress Cyclical Stress Maximum Stress Mean Stress 0 025 05 075 1 125 0 05 1 15 2 25 R0 Unidirectional Stress Mininum Stress Cyclical Stress Maximum Stress Mean Stress-15-1-05 0 05 1 15 0 05 1 15 2 25 R-1 Fully Reversed Stress Mininum Stress Cyclical Stress Maximum Stress Mean Stress Mean Stress 1 -12 0.

Critical Buckling Stress Calculator

Mechanics Of Materials Strain Mechanics Of Slender Structures Boston University

Stress Relaxation An Overview Sciencedirect Topics

Http Www Uobabylon Edu Iq Eprints Publication 12 24838 639 Pdf

Https Www Egr Msu Edu Pkwon Me471 Lect 206 3 Pdf

Elastic Moduli Young S Modulus Shear Modulus Videos And Examples

Nondestructive Evaluation Physics Materials

Https Www Egr Msu Edu Pkwon Me471 Lect 206 3 Pdf

Analysis Of Singly Reinforced Beam Working Stress Method

Stress Amplitude An Overview Sciencedirect Topics

Method Of Obtaining Magnitude And Direction Of Principal Stress Rosette Analysis Kyowa

Mechanics Of Materials Stress Mechanics Of Slender Structures Boston University

Solved Question 80 1 Point The Stress Ratio R R Mini Chegg Com

Stress Cycles With Different Stress Ratios Of R 0 1 And Download Scientific Diagram

Stress Amplitude An Overview Sciencedirect Topics

Mean Stress Corrections And Stress Ratios

0 comments